A Buyer's Guide to Product Configuration Software for Manufacturers

Choosing the right product configuration software is one of the most strategic technology decisions a manufacturer can make.

A high-quality product configurator transforms how you sell customizable products, streamlines operations from order capture through production, and creates competitive advantages that compound over years. On the flip-side, the wrong choice can lead to technical debt, frustrated customers, and missed revenue opportunities that persist until you undergo another expensive platform migration.

The challenge is that the product configuration software market is nuanced and fragmented. CPQ platforms, visual commerce solutions, ERP-native configurators, and standalone configuration tools all claim to solve manufacturers' needs. Worse, vendors use similar terminology to describe wildly different capabilities.

We put together this guide to help you make an informed decision on which type of software is best for your business. Whether you're a door and window manufacturer needing dimensional customization with AR visualization, a furniture company handling complex material combinations, or an industrial equipment producer requiring engineering-grade technical configuration, we'll help you find the framework for choosing software that actually works.

Understanding the Product Configuration Software Market

The product configuration software market reached $1.1 billion in 2024 and is projected to grow to $3.3 billion by 20311. This growth reflects an increasing demand for customizable products, the shift toward digital commerce, and manufacturers' need to handle configuration complexity at scale.

But here's the thing: "product configuration software" describes multiple related but distinct solution categories. Each has different strengths and trade-offs. Let's take a look.

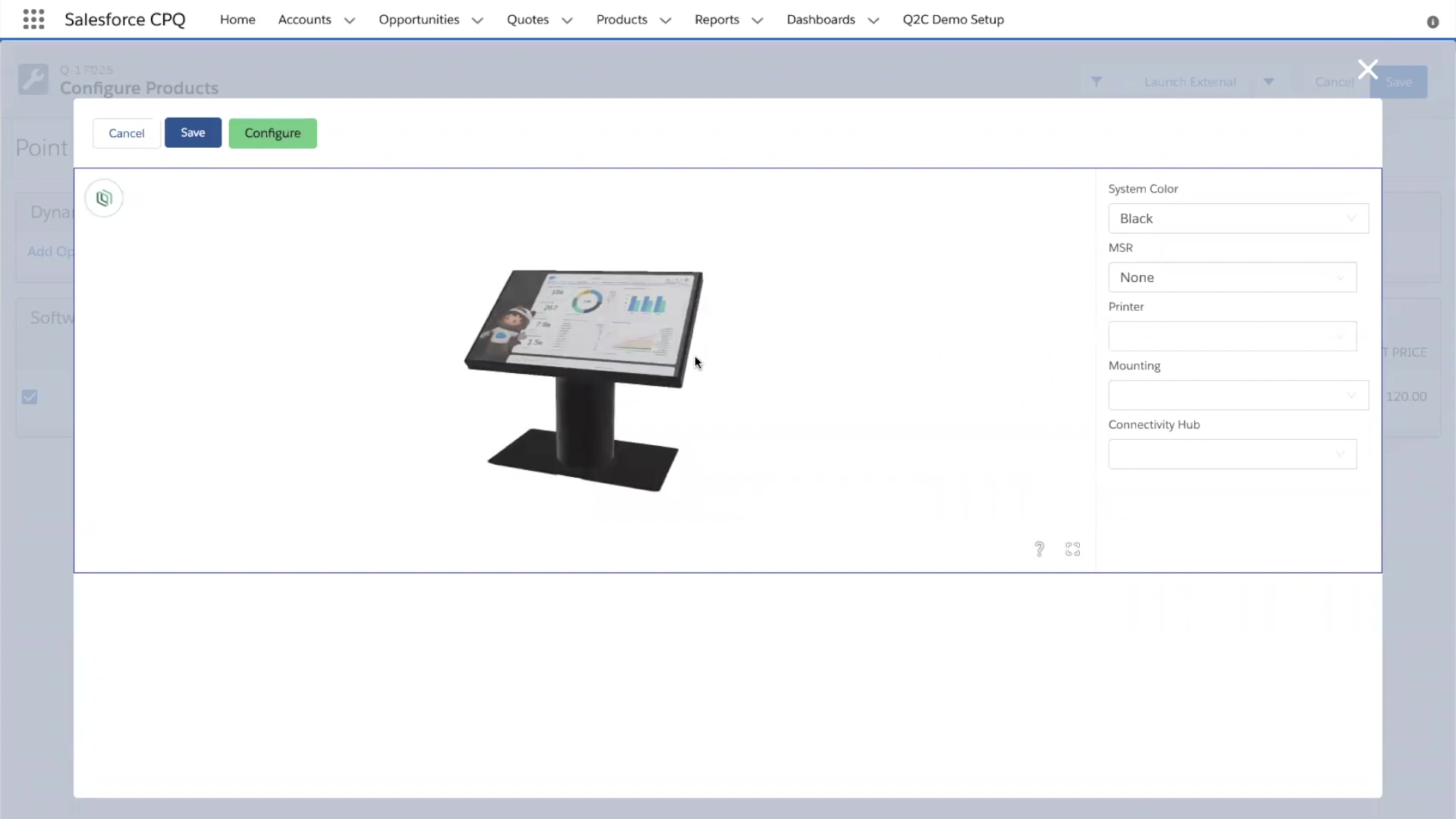

CPQ (Configure, Price, Quote) Platforms

CPQ platforms focus on the quote-to-cash process for configurable products. Think Salesforce CPQ, Tacton, Oracle CPQ, and Conga.

They excel at complex business rules, dynamic pricing with discounting logic, quote generation, and CRM integration for sales workflows. If your primary need is B2B sales processes with rep-driven workflows, CPQ makes sense.

The downside? Visual capabilities are often limited. Consumer-facing experiences can feel clunky. Implementation complexity tends to be high.

Visual Commerce Platforms

Visual commerce platforms like Threekit specialize in customer-facing product configuration experiences, offering exceptional 3D visualization, AR capabilities, and eCommerce integration.

These platforms are purpose-built for converting browsers into confident buyers through interactive product experiences. They deliver photorealistic 3D rendering, AR for visualizing products in customer spaces, and seamless integration with manufacturing systems including ERP, CAD, and production workflows.

Pricing complexity is handled, though it's not the primary focus (vs. a CPQ platform, which specializes in this). The real strength with visual product configurators is the customer experience that drives conversion.

ERP-Native Configurators

Systems like SAP, NetSuite, Microsoft Dynamics, and Epicor often include configuration modules. They integrate tightly with inventory, pricing, and production planning because they're part of the same system.

You get single-vendor support and built-in production workflow integration. But customer-facing experiences are often basic, visualization capabilities are typically limited, and flexibility is constrained by the ERP platform itself.

Standalone Configuration Engines

Solutions like DriveWorks, Configure One, and Logik.io focus specifically on configuration logic and rules. They're platform-agnostic and offer sophisticated rule handling with deep configurability.

The catch? They require integration with visualization, eCommerce, and other systems. The customer experience depends entirely on your front-end implementation.

Which Type is Right for You?

For most manufacturers selling configurable products online or through dealer networks, visual commerce platforms provide the most complete solution. They deliver the customer experience quality that drives conversion while maintaining the manufacturing integration and business logic capabilities that CPQ and ERP systems provide.

The proof? Manufacturers using platforms like Threekit see up to 56% more leads compared to standard websites.

Essential Features and Capabilities to Look For in Configuration Software

Not all configuration software provides the capabilities manufacturers actually need. Here's what matters most.

Configuration Logic and Business Rules

The configuration engine is the brain of your system. It needs to handle compatibility rules, dependency rules, constraint rules, calculation rules, and pricing rules without breaking a sweat.

Here's what to look for: Non-technical users should be able to create and modify rules without coding. Look for declarative rule languages or visual rule builders. The system needs rule testing and validation capabilities to ensure configurations work before deployment. Performance must remain strong even with thousands of configuration options.

For manufacturers with extremely complex products, platforms like Threekit partner with specialized commerce logic engines like Logik.io to handle the most sophisticated scenarios.

3D Visualization and Rendering

Visual product representation is non-negotiable. Your models need to look real—not like video game graphics.

As customers make selections, 3D models should update instantly. No delays, no lag. Customers need to rotate products, zoom in for detail, and see different perspectives. Colors, wood grains, metal finishes, and textures must render faithfully because inaccurate representation creates customer disappointment.

All of this must happen smoothly without requiring high-end hardware or causing page load issues.

Augmented Reality (AR) Capabilities

AR has moved from novel to expected, particularly for furniture, doors, windows, and products where spatial context matters.

Mobile AR support should work on iOS and Android devices. Virtual products need to appear at the correct size in real spaces and integrate with real lighting conditions. Launching AR shouldn't require app downloads or complex setup.

Threekit's AR capabilities let customers place configured products in their actual spaces using smartphones. For door and window manufacturers, the AI Home Vision feature goes further—customers upload photos of their homes and see how different configurations will look when installed.

CAD and Engineering Integration

Manufacturing requires that customer configurations translate seamlessly to production specifications.

CAD automation should automatically generate production-ready drawings from customer configurations. Support for major CAD platforms like SolidWorks and Autodesk Inventor is essential. The system should automatically create bills of materials with correct components, quantities, and specifications.

It needs to produce 2D engineering drawings, cut lists, and export configuration data in formats your production systems actually use.

ERP and Production System Integration

Configuration data must flow seamlessly into your business systems.

This means real-time pricing pulled from ERP systems, inventory integration that checks component availability, automatic order creation with complete specifications, and production order generation that triggers manufacturing workflows.

Platforms like Threekit provide proven integration patterns for major ERP systems including SAP, Oracle, NetSuite, and Microsoft Dynamics. They handle the complexity of keeping configuration data synchronized across systems.

eCommerce Platform Integration

For manufacturers selling direct or enabling dealers, eCommerce integration is critical.

The platform should integrate with major eCommerce platforms like Shopify, BigCommerce, Magento, and Salesforce Commerce Cloud. Configured products need to flow into shopping carts with complete specifications and accurate pricing. Product catalogs, pricing, and inventory should sync automatically.

Mobile and Responsive Design

Modern buyers research and configure on mobile devices. Full stop.

Mobile-first design with interfaces optimized for smartphones and tablets is essential. Touch-optimized controls, fast load times, and responsive performance on mobile networks are non-negotiable. Core functionality needs to work on all devices, with enhanced experiences on capable hardware.

Pricing and Quoting Capabilities

Dynamic, accurate pricing is fundamental.

Prices must update instantly as customers make selections. The system needs to support complex pricing models including base pricing, option upcharges, volume discounts, customer-specific pricing, and regional variations.

Professional quote generation should be automatic, with pricing logic that reflects your actual business model.

Analytics and Optimization

Understanding how customers interact with configurators enables continuous improvement.

Configuration analytics should track completion rates, abandonment points, popular options, and time-to-complete. A/B testing capabilities let you optimize interfaces for better conversion. Behavioral tracking helps you understand customer decision paths and feed business intelligence systems for strategic analysis.

Vendor Evaluation Criteria: What to Look For

Beyond feature checklists, evaluate vendors and platforms against these critical success factors.

Manufacturing Domain Expertise

Does the vendor understand manufacturing realities? Do they have experience serving manufacturers in your industry? Do they understand production workflows, CAD systems, and engineering processes?

Platforms purpose-built for manufacturing versus repurposed consumer tools demonstrate this expertise through their architecture and feature sets. It matters more than you think.

Implementation Support and Services

Implementation support often matters more than raw software capabilities.

Does the vendor provide implementation services or rely on partners? What's their track record with projects similar to yours? How long do typical implementations take?

Threekit provides implementation services drawing on experience across hundreds of manufacturer deployments, accelerating time-to-value and reducing implementation risk.

3D Modeling Capabilities and Support

Creating accurate 3D product models is often the most time-consuming aspect of implementation.

Can the vendor create 3D models, or must you source elsewhere? What's the quality of models they produce? How are model updates and maintenance handled? What model formats do they support?

Some vendors include modeling services. Others leave you on your own.

Scalability and Performance

Your configurator must handle growth.

How does performance scale with traffic volume? Can the platform handle your product catalog size? What are the limits on rules, options, or configurations? How do they manage peak loads during campaign launches or seasonal traffic spikes?

Total Cost of Ownership

Look beyond initial license fees.

Consider implementation costs for consulting, 3D modeling, and integration. Factor in ongoing license fees, support and maintenance costs, system administration burden, training costs, and integration maintenance over time.

Most manufacturers achieve payback within 6-18 months based on a combination of revenue increases and operational cost savings.

Platform Roadmap and Innovation

Evaluate the vendor's platform roadmap and innovation trajectory.

What's their product development direction? How quickly do they incorporate new technologies like AI and AR? Are they financially stable for a long-term partnership?

Threekit's recent launch of AI for Building Materials demonstrates continued innovation, incorporating AI-powered discovery, guided selling, and home visualization specifically for manufacturers.

The Evaluation and Selection Process

Structured evaluation processes dramatically improve selection outcomes. Here's how we recommend comparing different configurator platforms.

Start with Requirements Definition

Document exactly what you need before talking to vendors.

Define which products need configuration. Identify user personas and their needs. Map configuration requirements and complexity. List integration requirements. Specify visualization needs. Estimate volume expectations. Set timeline goals. Establish budget parameters.

Create a requirements document that becomes your evaluation scorecard.

Conduct Vendor Research and Shortlisting

Identify potential vendors and narrow to three to five finalists.

Use industry analyst reports, peer recommendations from manufacturers, industry publications, and vendor websites as research sources. Request product documentation, demos, pricing information, customer references, implementation timelines, and integration capabilities from shortlisted vendors.

Systematically Assess Each Finalist

Don't accept generic demos. Request customized demonstrations showing your actual products configured, your specific configuration rules in action, and integration with your systems.

Speak with current customers, particularly those in similar industries. Understand what the platform does well, what limitations exist, and whether they would choose the vendor again.

For high-risk or high-value implementations, proof-of-concept projects validate capabilities by implementing actual configuration rules and testing integrations with your systems.

Use your requirements document to score vendors objectively across functionality, integration capabilities, ease of use, implementation feasibility, total cost of ownership, and vendor stability.

Watch for Red Flags

Certain warning signs suggest problematic vendors or platforms:

- Vague on manufacturing integration - If vendors can't articulate specific CAD and ERP integration approaches, they may lack manufacturing expertise

- No customer references - Established vendors should readily provide references

- Unrealistic timelines - Complex configurator implementations take months, not weeks

- Won't provide pricing - Vendors who won't provide ballpark pricing early may have something to hide

- Poor visualization quality - If demo visualizations look amateurish, production quality likely won't be better

- Requires heavy customization - Platforms requiring extensive custom development for basic features create technical debt

- Limited integration capabilities - Closed platforms that don't integrate well force workarounds

- Weak domain expertise - Vendors who haven't implemented configurators for manufacturers like you face steep learning curves

Why Threekit Stands Out for Manufacturers

Throughout this buyer's guide, we've referenced Threekit multiple times. There's a reason for that. We've worked hard to ensure that the platform exemplifies what purpose-built manufacturing configuration software should deliver.

Built Specifically for Manufacturing

Threekit isn't a repurposed consumer tool. It's built specifically for manufacturers selling complex configurable products.

Exceptional 3D visualization and AR capabilities drive conversion. Proven integration patterns for ERP, CAD, and production systems are developed through hundreds of manufacturer implementations. Purpose-built optimization for building materials categories includes windows, doors, and kitchen and bath products.

Proven Results That Matter

Threekit clients see measurable impacts:

- Up to 56% more leads versus standard websites

- Significant conversion rate improvements through exceptional visualization

- Reduced engineering costs through CAD automation

- Lower return rates through accurate visualization

- Faster time-to-market for new products

Trusted by Industry Leaders

Industry leaders trust the platform: Kohler for kitchen and bath products, Sloan for plumbing fixtures, Fortune Brands across multiple product lines, and numerous door, window, furniture, and building materials manufacturers.

Making the Final Decision

Selecting product configuration software is a strategic decision with long-term implications.

The right platform drives revenue growth, streamlines operations, and creates competitive advantages. The wrong choice creates technical debt and missed opportunities.

Key Principles for Your Decision

- Prioritize strategic fit over feature counts. A platform with fewer features but excellent strategic alignment serves you better than a feature-rich misfit.

- Weight implementation expertise heavily. Software capabilities matter less than successful deployment.

- Think long-term. You'll live with this platform for years. Evaluate vendor stability, roadmap, and partnership potential.

- Get executive buy-in. Configuration software touches sales, marketing, engineering, and operations.

- Plan for change management. Technology is easier than organizational change.

- Set success metrics. Define how you'll measure success and commit to tracking throughout implementation and beyond.

The Bottom Line

The manufacturers thriving with configuration software are those who select platforms aligned with their strategic needs, partner with vendors who understand manufacturing realities, and commit to implementation excellence.

Ready to evaluate product configuration software for your manufacturing business? Explore Threekit's visual commerce platform, purpose-built for manufacturers with proven results across building materials, furniture, industrial equipment, and complex configurable products. Schedule a demo to see how Threekit can transform your product configuration experience.

Sources: