Opening Up Lean Manufacturing with Visual Commerce

Visual commerce plays a crucial role in lean manufacturing, a production method that aims to reduce time within the production system as well as response times from suppliers and to customers. By understanding and implementing visual commerce effectively, manufacturing processes can be streamlined and optimized for greater efficiency and productivity.

The Role of Visual Commerce in Lean Manufacturing

Understanding Visual Commerce

Visual commerce represents a transformative approach in the manufacturing landscape, leveraging digital assets to enhance customer engagement and streamline production processes. At its core, visual commerce involves the use of images, videos, 3D models, and interactive experiences to communicate product value and functionality to customers. This visual-centric strategy is not only about aesthetics; it's a practical tool for conveying complex information quickly and effectively.

For lean manufacturing, visual commerce becomes a pivotal element in reducing waste and improving efficiency. It enables manufacturers to provide detailed product insights without the need for physical prototypes, thus saving time and resources. Here's how visual commerce integrates with lean principles:

- Elimination of waste: By providing accurate visual representations, companies can reduce the number of physical samples and iterations needed.

- Value stream mapping: Visual tools help in outlining the entire production process, identifying bottlenecks and areas for improvement.

- Continuous improvement: Real-time visual feedback mechanisms allow for ongoing optimization of processes and products.

Tip: Start small with visual commerce by incorporating basic visual aids into your production workflow, and gradually expand to more sophisticated tools as you gauge their impact on your lean manufacturing goals.

Implementing Visual Commerce in Lean Manufacturing

The integration of visual commerce into lean manufacturing is a transformative step that requires a strategic approach. To begin with, it's essential to identify the specific areas within the manufacturing process that will benefit most from visual elements. This could include assembly lines, inventory management, or quality control stations. The following are five steps your company can take to begin implementing visual commerce.

- Assess current processes to determine where visual commerce can be integrated.

- Select appropriate visual commerce tools and technologies.

- Train employees on how to utilize these tools effectively.

- Monitor and measure the impact of visual commerce on the manufacturing process.

- Continuously refine and improve visual commerce strategies.

Tip: Always keep the end user in mind. Visual commerce should simplify the process, not complicate it. Ensure that the visuals are intuitive and enhance the workflow rather than disrupt it.

Remember, the goal is to create a seamless flow of information that is easily accessible and understandable at a glance. By doing so, manufacturers can foster an environment of continuous improvement and operational excellence.

Challenges and Solutions in Visual Commerce for Lean Manufacturing

Challenges of Implementing Visual Commerce

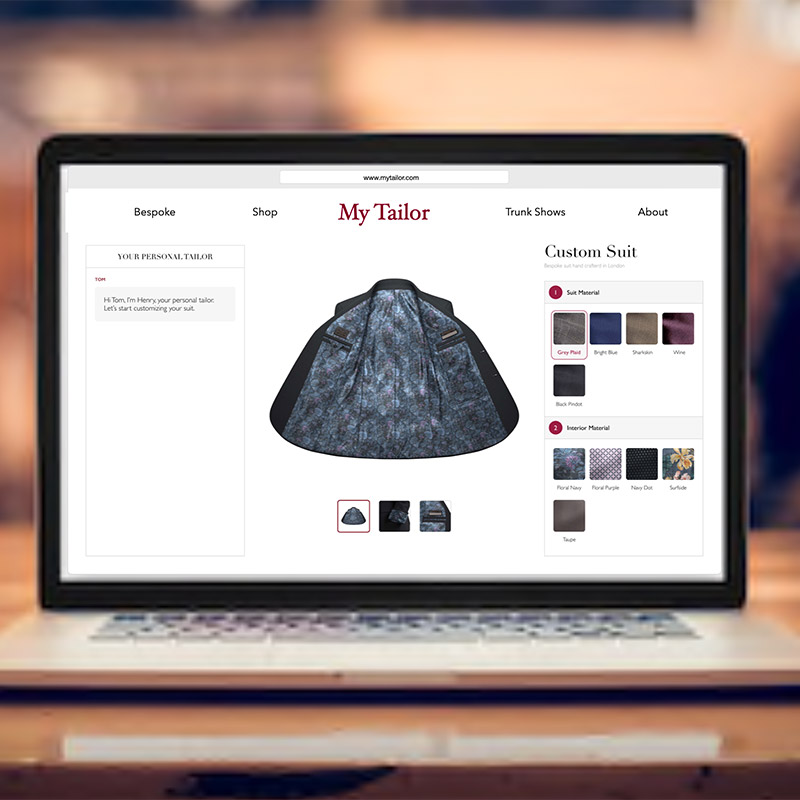

Visual commerce solutions play a crucial role in addressing the challenges of implementing visual commerce in lean manufacturing. By leveraging advanced technology and innovative platforms, businesses can overcome the complexities associated with visual commerce integration. One effective approach is to implement a visual product configurator that allows for seamless customization and visualization of products. Additionally, businesses can benefit from the use of a visual management system to display important KPIs and manage workload efficiently. These solutions contribute to improved efficiency and streamlined processes, ultimately enhancing the lean manufacturing environment. To ensure successful implementation, it's essential to address each challenge through a process flow chart, install countermeasures, and revise the process as needed. By embracing these solutions, businesses can optimize their visual commerce strategies and drive sustainable growth.

Best Practices for Visual Commerce in Lean Manufacturing

In the context of lean manufacturing, implementing visual commerce involves a strategic approach to enhancing workflow efficiency and reducing bottlenecks. One best practice is to implement a visual system, like Kanban, that controls the flow of work within a process, promoting continuous improvement and limiting work in progress.

Additionally, it is essential to standardize and segregate the layout of the manufacturing facility. This can be achieved by implementing 5S principles (Sort, Set in Order, Shine, Standardize, and Sustain), ensuring that every bay layout is standardized and visually managed to optimize workflow and reduce waste.

For structured quantitative data, a Markdown table can be used to compare the efficiency improvements before and after the implementation of visual commerce. This table should include key metrics such as lead time, cycle time, and inventory turnover, providing a clear comparison of the impact of visual commerce on manufacturing efficiency.

Visual commerce is revolutionizing the manufacturing industry, but it comes with its own set of challenges. Lean manufacturing processes require efficient and accurate visual representation of products, which can be a daunting task. However, with Threekit's advanced 3D visualization solutions, these challenges can be overcome. Our 3D experts specialize in creating precise 3D replicas of products, enabling manufacturers to streamline their visual commerce processes. Schedule a demo with Threekit's 3D experts today and experience the power of visual commerce in action.