Manufacturing Product Configurator: Definition, Types, Benefits & Features

Consumers spend up to 21% more on brands that offer a personalized customer experience. This makes product configurators a must for businesses with customizable product options.

When you give customers the opportunity to visualize the item they’re shopping for, makes them more confident in their decision, and enables you to increase your sales. Product configurators can be particularly helpful for manufacturers like yourself that sell products by parts or allow for item personalization.

So, if you're looking to streamline your sales process, improve customization, reduce the percentage of returns, and increase customer satisfaction, this article will help you out. Here we'll cover the different types of configurators, the inputs and outputs they need and produce, and the process to set up yours to positively impact your business.

Increase sales by delegating control.

Use Threekit to let your users design the product they want and build it for them.

Talk to us

What is a product configurator?

There’s essentially just one type of product configurator that can contain visuals or 3D models. In fact, “product configurator,” “visual configurator,” and “3D product configurator,” are three terms that are often used interchangeably.

- How it works: The customer can select parts from a list without restrictions or dependencies. For example, they can customize a computer and choose certain parts of it to their liking without any limitations.

- How rules and logic play a role: Shoppers can select items from a list that follows a logic or an algorithm. For instance, customers can’t buy a 512 GB SSD on certain models, they can just get a 256 GB SSD or a 512 GB HDD. In this case, the configurator alerts them of incompatibilities.

- Adding parametric features: This component takes dimensions and spatial considerations into account. For example, front-entry doors with specific thickness, height, weight, and specific dimensions of the glass that goes in the door.

Now, let’s explore the difference between visual, 3D, and standard product configurators:

1. Visual configurators

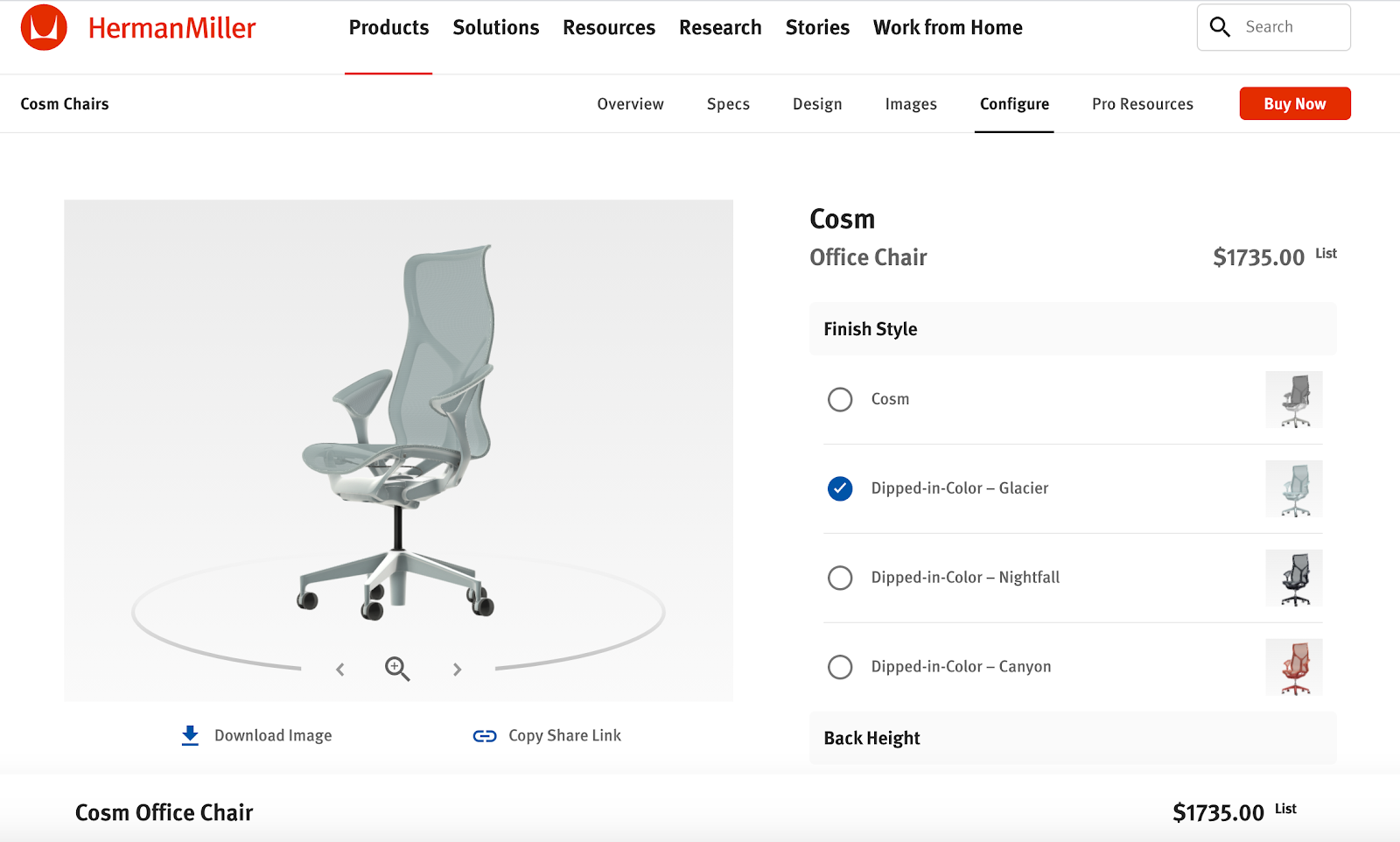

Use visual photography to implement and showcase your customer changes in real-time. Source

A visual product configurator is a type of product configurator that includes graphics, visual photography, or computer-generated images (CGI) of your offering. It helps users see how their choices affect the appearance of the end product in real time. This type of configurator is mostly used for customizable, manufacturing products like cars, furniture, electronics, or clothing.

Using a visual configurator like Threekit, a top product configurator in the field of visual commerce, gives you access to a composable suite of tools to organize and personalize your products. With Threekit, you can add the dependencies and rules you need for your products and integrate it with your internal tech stack.

2. 3D product configurator

Manufacturers can use Threekit to create 3D models of their products and set up configurations. Source

This one is more of a subset of visual configurators. It lets you set up product configurations using 3D models. So, instead of using static images, users can interact with a three-dimensional view of your product and offer a more realistic experience.

As 3D model configurators provide an immersive experience, these are particularly helpful when manufacturing products with spatial considerations, small parts, or details. For example, house doors, computers by parts, furniture with design details, architecture, or complex machinery.

You can use Threekit’s visual engine to create 3D models of your products and set the configurations in our easy-to-use platform.

3. Product configurator

Use product configurators on manufacturing products with spatial capabilities and rules. Source

This is the umbrella term for the previously mentioned types. A product configurator refers to the software or tool where you configure your products following a set of rules and dependencies. This tool can be used for various types of products that require a certain level of customization from consumer goods like choosing the size of a detergent bag, to more complex solutions such as car parts.

In a configurator, you can list all the parameters and dependencies you need, and make it available to the user in an accessible and easy-to-use front-end. The configurator will then create a real-time representation of the user’s order in a visual or listed way depending on your settings.

A product configurator like Threekit makes it easy for you to configure your product’s parameters and rules in a no-code engine and simplifies your work by automating sales outputs. This means you can generate bills or print-ready instructions, track orders, or allow the shopper to bundle products without taking on any additional work.

Inputs and outputs of your product configurator software

For your configurator to work, you need to feed it with certain files and data for it to work (inputs). Then, the configurator will give you a list of files and information that allows you to continue with the sales process (outputs). Let’s take a brief look at these.

Product configurator inputs:

- CAD (computer-aided design) files: Enter digital blueprints of your products to design, model, and configure your product. These files should contain precise data about your offering’s dimensions, materials, and technical instructions. These files enable engineers and designers to edit your 3D model.

- Enterprise resource planning (ERP) or material resource planning (MRP) data: This information helps your product configurator manage the production process. This gives the tool access to accurate information that it can consult to check inventory, pricing, and lead times to make accurate offers. MRP data also helps you reduce shortages and move excess materials. This data also allows the configurator to offer shoppers cost estimates, delivery dates, and component compatibility in real time.

- Product catalog data: Share all of your product’s information with the configurator to set descriptions, list attributes, set prices, and determine configuration rules for compatibility. This makes it easy for shoppers to buy and customize products accurately and efficiently.

- Product information management (PIM) data: Similar to ERP/MRP data but strictly related to your product’s information. This input helps your product configurator manage product-related information, including product descriptions, attributes, visuals, and marketing copy. This data centralizes and organizes product information to ensure it’s presented the same way across the different sales channels.

Product configurator outputs:

- CAD renders: Your product configurator will generate 3D renders or visualizations of your products. A render is usually a realistic representation of your product’s design to show end-users their choices in real time.

- Sales bills of materials (BOM): This is a structured list of all materials, components, and sub-assemblies you need to manufacture the customized product. The BOM usually included detailed information regarding part numbers, quantities, descriptions, and any relevant assembly instructions.

- Cut sheet data: If your materials need to be cut or shaped in a particular way, you need your product configurator to generate cut sheet data. This output provides you with specific instructions on how to manufacture the customized product for your shoppers.

- Configure, price, quote (CPQ) data: The configurator should integrate with a CPQ solution to come up with accurate price quotes based on the customized product so customers can approve or deny the offer.

How product configurators work in manufacturing

Embracing the digital transformation in manufacturing and setting up a product configurator for your business is easier than you may think. Make sure you have your product information at hand and follow this list of steps:

1. Work on your product definition

The first step of the configuration process is to define your base products. An accurate product definition lets you build a proper configuration with the right customizing options. It also helps your customers easily find your product and feel satisfied with the result.

For example, if you manufacture custom-made tables, use this stage to outline what you sell: Modern, tailor-made wooden, glass, marble, and steel dining tables from 59” to 590”.

2. Identify your options

Determine all the different variations, add-ons, features, and options your customers can choose from. Include all the different materials, sizes, colors, and functionality.

Following the same example, make a list of all the parts and potential variations, here’s a summarized one:

| Parts/ options | Sizes | Material | Colors/variations | Shape |

|

Tabletop

|

L: From 36 to 590 inches W: From 36 to 531 inches D: From 1.5 to 20 inches |

Wood: Stainless steel Marble Glass |

If wood:

If steel:

If Marble:

If glass:

|

Rectangle Square Circle Custom shaped |

| Legs/ Base |

LxWxD: From x to x |

Wood Steel Marble |

If wood:

If steel:

If Marble:

|

Cylindric Custom Rectangular Attachable |

3. Set rules and constraints

Determine your rules and limitations for each option. Also, come up with potential combinations so you can guarantee your customers can make feasible products. Make a map of all the limitations, for example: You can only mix crystal legs with pine wood because the other materials are too heavy and might break.

4. Enter data into the configurator interface

Once you’ve defined your product, its variations, and constraints, you can input this information into the configurator. Here you should guarantee that your data is accurate and that all constrictions are accurately loaded.

5. Toggle real-time validation

Implement real-time validation on your tool so it can check the viability of a customer’s selection against your inventory and set of rules and constrictions. This means a customer should get an alert in real-time notifying them their selection is invalid if they choose crystal legs with a marbled tabletop.

6. Set your dynamic visualizations

If you have 3D models or 2D visual photographs, input them into the system. If not, you can use Threekit’s visual engine to create CGI product visualizations in 2D or 3D following previously entered guidelines. This will allow your customers to see exactly how their envisioned product will look like.

7. Determine pricing rules and calculations

Assign prices to each of the options and all the different variations. You can assign prices per pound, inch, feet of materials, or piece quantity to simplify your calculations. For example, if you say an inch of marble is $5, then a customer who buys a tabletop of 35” will be charged $175 for the top. You can also add manufacturing costs to the mix or as an additional service cost.

8. Generate quotes

Make sure your product configurator integrates with your CPQ system and presents customers with an automated quote. Making your customers wait for the price can potentially cause them to abandon the page or delay the sales cycle.

If you’re using Threekit as your product configurator, you can easily generate print-ready files, bills, or assembly instructions across all sales channels.

Factors to consider when choosing a product configurator solution

There are many qualified product configurator software at different price points available in the market. Choosing the right one for your business depends on your unique needs, product complexity, integrations with your tech stack, and business size. Let’s explore these factors in more detail:

1. Product complexity

Take your time when defining your product to understand its complexity and ensure you’re taking every single aspect into account. The more detailed you can be about each option and variation, the better customer experience you’ll offer. Study the details and limitations of each material and determine the accurate constraints, compatibility, and availability.

For example, test your table materials in different sizes, you might be able to assemble a wooden tabletop with a marbled base but the shipping cost might be a lot higher, so you should take that into account. Or, you discover that you only build crystal tables on-demand and it takes 90 days to get the materials and assemble the product.

2. Integrations

Your product configurator should integrate with your existing systems and accept your usual inputs like your CRM, ERP, or CPQ. If you’re using Threekit, it integrates with Salesforce, Shopify, Magento, Bigcommerce, Oracle, SAP, and more. So, list all your internal tools and determine if you can connect them to the product configurator you’re prospecting.

3. Real-time validation

As covered, this feature enforces rules and validates configurations in real time. If you want to give your customers answers about the viability of their choices as they customize the product, then your product configurator needs to support this feature.

4. Product bundling

If you have the type of business where customers buy multiple products at once, you need your configurator to support product bundling. This allows shoppers to combine multiple SKUs in a single edit and order.

For example, if you sell custom-made tables and chairs for restaurants, you’ll benefit from offering product bundling as your users will likely want to use the same materials or colors for both SKUs.

5. Scalability

You want a product configurator that grows with you and accommodates increasing demands. Ask providers about the size of the businesses they serve and the amount of data they regularly handle. This will give you insights into whether or not it can support your company’s information.

Drive customer satisfaction with a manufacturing product configurator

Creating personalized customer experiences can result in more sales. Therefore, product configurators play a pivotal role in modern manufacturing businesses.

In this article, we've delved into the three types of product configurators: visual, 3D, and standard, each catering to different needs and preferences. These solutions feed from inputs like CAD files, ERP, MRP, or PIM data; and output CAD renders, BOM, or CPQ data.

If you’re thinking of setting up a product configurator, you need to define your product and its customizing options, set rules and constraints, enter the data into the system, and set your visuals. Then, you need to set the right price and make sure it validates rules in real time and generates automated quotes.

When looking for a product configurator, you should think of factors like product complexity, integrations, real-time validation, product bundling, and scalability. If you're looking to harness the power of configurators, consider a solution like Threekit to empower your customers to visualize and design the products they want in powerful 2D and 3D models. And, get ready to see your revenue and customer satisfaction levels grow.

Increase sales by delegating control.

Use Threekit to let your users design the product they want and build it for them.

Talk to us

Frequently asked questions about manufacturing product configurators

What is a manufacturing product configurator?

A manufacturing product configurator is a system that allows manufacturing companies to offer their customers the ability to design, customize, and configure complex products based on their needs. This tool makes it possible to create tailor-made products within the constraints of the manufacturing processes and available components.

Can product configuration tools integrate with existing digital workflows?

Yes, product configuration tools can integrate seamlessly with existing digital workflows. Not all product configurators integrate with the same tools, but one like Threekit will integrate with your:

- Sales enablement platforms

- ERP system

- CPQ platforms

- PIM system

These connections allow your manufacturing team to follow all workflows and come up with configurable products without altering your business processes.

How do manufacturing product configurators contribute to customer satisfaction?

Manufacturing product configuration can significantly contribute to customer satisfaction in multiple ways:

- Freedom of customization. By offering your shoppers to create the product they truly want and need, you can gain greater customer satisfaction as you’re more likely to meet their expectations.

- Real-time feedback. Your configurator shares exactly how much a product will cost, the requirements to make it happen, and any recommended features in real time. This helps reduce the likelihood of disappointment upon delivery.

- Fast quoting. As your configurator can generate instant price quotes, your customers don’t need to wait days or weeks to decide on your product. This leads to faster and greater customer satisfaction.

- Error-free products. Since product configurators are powered by automation, it reduces the possibility of errors in the manufacturing process, so customers are more likely to receive exactly what they ordered.