Case Study

When the founders of BOSTONtec put their prototype workstation in the back of a truck and hauled it across the state to show it to a prospect, they knew they had something special.

Intro

BOSTONtec, a company that designs and builds ergonomic workstations, was started in 1993 because the founders recognized how people sit, stand, and do their work has a significant impact on employee health and happiness. As one of the first companies in this space, they grew to serve a vast market by providing highly-configurable workstations across the US.

Background

It all started with the founders of BOSTONtec put their first prototype workstation in the back of a truck and sought out a premier outdoor clothing gear and clothing brand at a conference, to show them how it worked.

The brand was so impressed that they bought it and today—nearly 30 years later—the workstations are still being used.

BOSTONtec continued to expand their product line because they understood that each customer has unique wants and needs. Today they offer a nearly infinite number of workstation setups. And as a result, sales—and their dealer network of resellers—exploded.

But with the growth of its product line and reseller channels, the sales and marketing team struggled on a few fronts: buyers wanted to see renderings of their custom workstations and dealers wanted to familiarize themselves with the vast catalog.

With no solution in place, BOSTONtec would tie-up their in-house application engineer with endless requests for drawings, even for simple configurations.

For the company who “can do anything” they knew they could do better.

Solution

BOSTONtec engaged a small agency prior to Threekit, and found that although 3D visuals improved the customer’s experience, their solution lacked the functionality required to map out all of the potential combinations, constraints, and product dependencies. BOSTONtec was conditioned to hear ‘sorry, it can’t be done’.

After a recommendation, the team found Threekit. Following a successful proof of concept using their existing manufacturing CAD files, the BOSTONtec team realized that almost their entire 64-page catalog could be digitized and made accessible to customers and dealers alike via Threekit’s 3D platform. They also learned the value of working with a team that emphasizes that it can be done.

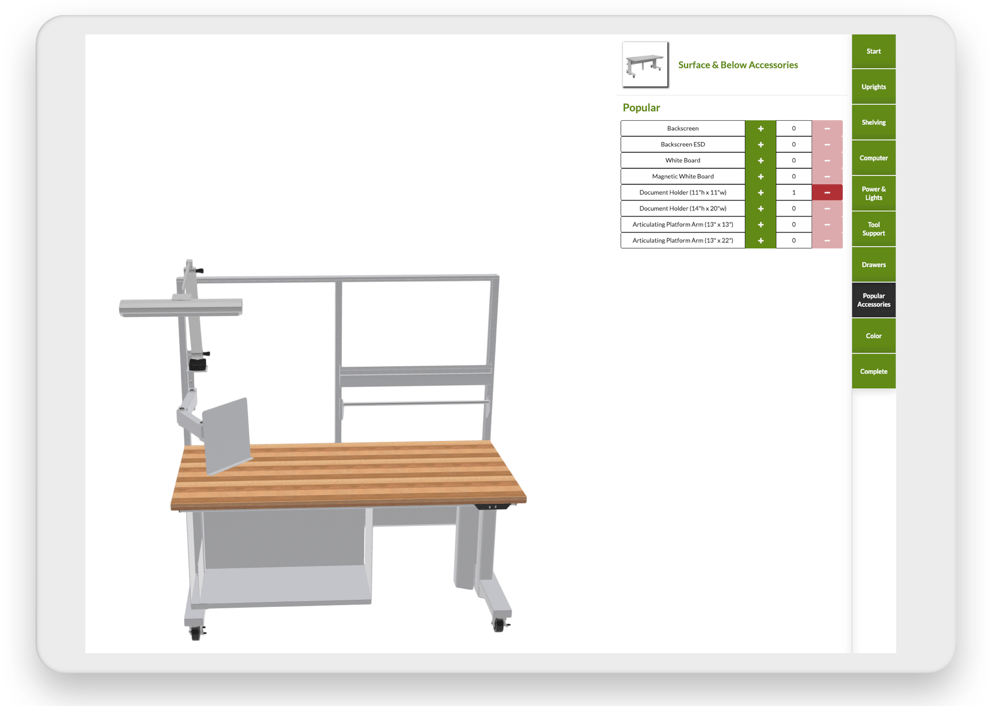

The solution married the idea of a digitized catalog of components with an intuitive step-by-step interface that guides the user through an interactive experience. Each product is “assembled” in real-time 3D as the user selects, drags, drops, and places new components to their satisfaction.

BOSTONtec's entire 64-page catalog could be digitized and made accessible to customers and dealers alike via Threekit’s 3D platform.

Outcome

Today, BOSTONtec’s configurator, powered by Threekit, is fuelling a new era of expansion. The configurator allows users to design stations utilizing about 80% of BOSTONtec's standard product line and the company saw a 30% increase in quote requests in just the first year.

The configurator has become an extension of their sales and marketing team, so quotes can be made on the spot, even when the office is closed. Their entire 64-page catalog is digitized. This has enabled them to up-sell, win more business and ultimately improve the brand’s image.

All elements of the configurator are controlled in a single location meaning new components can be added and implemented with ease and the step-by-step interface is fully-controllable. Each product is “assembled” in real-time 3D as the user selects, drags, drops, and places new components to their satisfaction. This ensures BOSTONtec is prepared for the configurations of today and tomorrow.

Before Threekit, we had to manually design workstations, but now, our customers and dealers can build and visualize their workstation instantly in 3D. This visual experience puts us head and shoulders above the competition because when our prospects get their hands on our workstations, they never let go.”

Meagan Steffes, Project Manager at BOSTONtec