How 3D Visualization Reduces Sample Costs for Door and Window Manufacturers

The door and window manufacturing industry faces a persistent and expensive challenge: sample costs are spiraling out of control. Between producing physical prototypes, shipping them to showrooms and dealer networks, maintaining inventory, and updating samples every time a new finish or configuration launches, manufacturers are losing money on a process that doesn’t scale with modern buying expectations.

The numbers tell a sobering story. Wholesale prices for wood doors and windows have risen 49% from January 2020 to January 2024, while metal door and window prices increased 59% during that same period, according to the Federal Reserve Bank of St. Louis. With the U.S. windows and doors market valued at $27.71 billion in 2023 and projected to reach a CAGR of 3.4% through 2030, manufacturers can't afford to maintain the status quo of physical sample production.

3D visualization and virtual photography are transforming how door and window manufacturers approach sample creation, showroom displays, and dealer enablement. Companies using these technologies are reducing sample production costs, accelerating time-to-market for new products, and enabling unlimited product variations without producing a single physical sample. This opportunity isn't theoretical. It's happening right now across the building materials industry.

Let's explore exactly how 3D visualization eliminates traditional sample costs, why this technology has become essential for competitive manufacturers, and what the financial impact means for your bottom line.

The Hidden Costs of Physical Samples

Before diving into the solution, it's worth understanding the full scope of physical sample expenses. Most manufacturers only track direct production costs, but the financial burden extends far beyond the factory floor.

First, there's the cost of actually producing samples. For a door manufacturer offering multiple wood species, finishes, glass options, and hardware configurations, producing even a fraction of the possible combinations requires a significant investment in materials and labor. A single custom door can cost $500-$2,000 to produce, and that's before any customization. Window manufacturers face similar economics, with unique configurations requiring specialized materials and assembly.

Second, physical samples require storage. Manufacturers need warehouse space to hold inventory before distribution, and then showrooms and dealer locations need additional space to display samples. Commercial real estate isn't cheap. The average warehouse space costs $9.12 per square foot annually, according to Cushman and Wakefield, and showroom space in high-traffic retail locations commands significantly more. A manufacturer with 200 dealer locations, each holding 50 sample units, is paying for storage across 200+ facilities.

Third, samples require shipping and logistics. Every new product launch means coordinating shipments to potentially hundreds of locations. Every discontinued product means coordinating returns or disposal. Freight costs have increased substantially in recent years, with the Bureau of Labor Statistics reporting significant transportation cost inflation throughout 2024.

Fourth, samples become obsolete quickly. When you introduce a new finish, update hardware options, or modify specifications, existing samples become outdated. They must be replaced, creating a continuous cycle of production, distribution, and disposal. The 2024 WDMA U.S. Window & Door Industry Market Study notes that manufacturers shipped 64.8 million units in 2023, with continuous product evolution across categories, each evolution requiring sample updates across dealer networks.

Fifth, physical samples limit product visualization options. If you offer 5 door styles, 8 wood species, 12 finish options, 6 glass types, and 10 hardware choices, you have over 28,000 possible configurations. Producing physical samples for even 1% of these combinations is financially impossible. So customers never see most options, or you limit configurations artificially to match sample availability.

The economic reality is that traditional sample programs don't scale with customer expectations or product possibilities. According to the National Association of Home Builders, 91% of door and window manufacturers reported growth over the past five years. However, many struggle to maintain profitability due to rising operational costs, including sample programs.

How 3D Visualization Eliminates Sample Production Costs

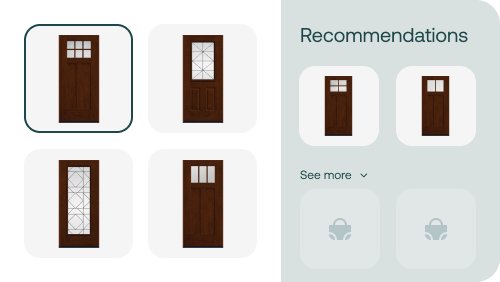

Virtual photography and 3D visualization fundamentally change the sample economics. Instead of producing thousands of physical units, manufacturers create digital twins of their products that can generate unlimited photorealistic images of any configuration.

Here's how it works: manufacturers provide design files (CAD drawings, product specifications, or even photographs of existing products) to create 3D digital models. These models are built to specification, incorporating accurate dimensions, materials, textures, and hardware. Once the digital model exists, it becomes the source for all product visualization needs.

From a single 3D model, you can generate thousands of product variations instantly. Want to see that door in cherry wood instead of oak? Changed instantly. Need to visualize it with brushed nickel hardware instead of bronze? Done in seconds. Looking to show 15 different glass options? All are available immediately. According to research comparing traditional and virtual photography costs across 17 cities globally, virtual photography costs 6x less than traditional photography on average. For manufacturers, the savings are even more dramatic.

Traditional product photography typically costs $100-$400 per image, according to multiple industry sources. Virtual photography using platforms like Threekit costs approximately $0.01 per image. That's 1,000x cheaper per photo. A manufacturer producing 10,000 product images annually saves between $990,000 and $3,990,000 by switching to virtual photography.

But cost per image doesn't tell the whole story. With virtual photography, you're not just saving money on individual images. You're eliminating entire categories of sample-related expenses:

Zero Physical Production: No more manufacturing samples that will never generate revenue. No material costs, no labor costs, no production capacity diverted from revenue-generating orders.

Zero Shipping & Logistics: Digital files transmit instantly to any location worldwide. No freight costs, no coordinating deliveries to hundreds of dealer locations, no managing returns of obsolete samples.

Zero Storage Requirements: Digital assets live on servers, not in warehouses or showrooms. Dealers access unlimited product variations without dedicating precious square footage to physical inventory.

Infinite Configurations: Show every possible product combination to every customer without producing a single additional sample. The 28,000 door configurations mentioned earlier? All available digitally with no incremental cost.

Instant Updates: When you launch a new finish or modify specifications, digital models update instantly across all platforms. No coordinating physical sample replacement across hundreds of locations.

Threekit's virtual photography platform exemplifies this approach for building materials manufacturers. The platform accepts product design files and helps manufacturers generate unlimited photorealistic images from any angle and configuration in seconds. One Threekit client generated 50,000 product images in one week using the platform, a project that would typically take a team of five photographers over a month. That's 21 times faster than traditional photography, with costs reduced by 99%.

The building materials industry is recognizing this opportunity. Threekit recently launched AI for Building Materials, specifically addressing windows, doors, kitchen and bath, tile and flooring, and other categories where product complexity and configuration options create sample challenges. Leading manufacturers like Kohler, Sloan, and Fortune Brands use Threekit to power immersive digital experiences, with some seeing up to 56% more leads compared to standard site visitors (PR Newswire).

Reducing Showroom and Inventory Requirements

Physical samples don't just cost money to produce. They also create downstream expenses in showrooms and inventory management. 3D visualization addresses these costs by transforming how products are displayed and selected.

Traditional showrooms require significant physical space. A door and window dealer might dedicate 3,000-5,000 square feet to sample displays, with products arranged by style, material, and finish. Commercial real estate at this scale represents substantial fixed costs, including rent, utilities, insurance, and maintenance.

Virtual showrooms eliminate or dramatically reduce these space requirements. Instead of physical samples, dealers can implement digital displays using large screens or tablets where customers explore unlimited product configurations interactively. A single 65" display showing 3D product visualization can replace dozens of physical samples, freeing up space for other revenue-generating activities.

The economic impact is measurable. If a dealer pays $25 per square foot annually for showroom space and reduces their sample area by 2,000 square feet through digital visualization, that's $50,000 in annual savings. Multiply this across a network of 200 dealer locations, and manufacturers collectively save $10 million annually in real estate costs passed along to dealers.

Inventory management costs also decrease substantially. Physical samples require tracking, cataloging, maintenance, and eventual disposal. Someone needs to make sure samples are clean, undamaged, and current. When products are discontinued or updated, inventory must be identified, removed, and replaced. These administrative tasks consume staff time and create operational complexity.

Digital visualization eliminates this burden. Product libraries update automatically when manufacturers release new options or retire old ones. There's no inventory to track, no samples to maintain, no disposal logistics. Dealer staff can focus on customer engagement rather than sample management.

For manufacturers, this creates a compelling value proposition for dealer networks. Dealers reduce their operational costs while simultaneously offering customers access to vastly more product options. That's a win-win that strengthens dealer relationships and competitive positioning.

The 2024 Window + Door Industry Pulse survey noted that manufacturers are increasingly focused on dealer support and enabling digital buying experiences. By providing 3D visualization tools, manufacturers help dealers compete more effectively while reducing their own sample program costs.

Enabling Instant Visualization of Custom Configurations

The most powerful aspect of 3D visualization isn't cost savings. It's enabling product experiences that are impossible with physical samples. When customers can see their exact custom configuration before ordering, confidence increases, sales cycles shorten, and returns decrease.

Consider the buying process for custom doors or windows. Customers typically start with general preferences, style, size, and material, then refine choices around finishes, hardware, glass options, and accessories. With physical samples, they might see 20-50 options total, then extrapolate to imagine their exact configuration. This process requires significant mental work and leaves room for uncertainty.

With 3D visualization and product configuration, customers see their exact product in real time as they make selections. Choose French doors in mahogany? See it rendered instantly. Add decorative glass with a brass finish? Watch it update on the screen. Change dimensions to fit a specific opening? The visualization adjusts immediately with accurate proportions.

This real-time visualization builds purchase confidence in ways physical samples cannot. According to Threekit's AI technology impact data, manufacturers using immersive digital experiences see up to 56% more leads compared to standard website visitors. This isn't just about attracting more browsers. It's about converting more browsers into confident buyers.

The visualization doesn't stop at product configuration. Augmented reality (AR) capabilities let customers place virtual products in their actual spaces using smartphones or tablets. A homeowner can visualize how new windows will look on their house exterior, or see how a custom door complements their entryway. This contextual visualization eliminates the abstraction of showroom samples where products appear in generic settings.

For window manufacturers, this is particularly valuable. Window selection depends on how products will look in specific architectural contexts. Seeing a window sample in a showroom provides limited insight compared to visualizing it on the actual house where it will be installed. AR eliminates this gap, showing customers exactly what they're buying in the environment where they'll live with it.

The business impact extends beyond individual sales. When customers can explore unlimited configurations digitally, they often discover options they wouldn't have considered with limited physical samples. Average order values increase because customers aren't constrained by sample availability. They can select the best product for their needs rather than the best option from a limited set.

Product returns decrease for similar reasons. When customers see photorealistic visualizations of their exact product before ordering, expectations align with reality. The "it didn't look like I expected" returns that plague many manufacturers happen less frequently when customers have interacted with accurate digital representations.

For door and window manufacturers specifically, Threekit's AI for Building Materials includes AI Discovery and Guided Selling capabilities that help customers navigate various specifications and options. Users describe what they need in plain language ("I want a modern, energy-efficient window with black trim") and receive relevant, configurable product options. This intelligent guidance helps customers find the right product faster while reducing the burden on sales staff.

Accelerating Time-to-Market for New Products

Physical sample production creates significant friction in new product launches. When you introduce a new finish, style, or configuration, you must coordinate sample production, distribution to dealers, and showroom setup before customers can interact with the product. This process takes weeks or months and represents a substantial capital investment before generating a single sale.

3D visualization eliminates this lag. When you launch a new product, you create or update the digital model and deploy it across all digital channels immediately. Dealers have access instantly. Customers can configure and visualize the product within days of the launch announcement. There are no production delays, no shipping coordination, and no waiting for samples to arrive at dealer locations.

This acceleration provides competitive advantages. In fast-moving markets where design trends evolve rapidly, getting new products to customers first captures market share. According to Market Research Future, the windows and doors market is projected to expand from $221.9 billion in 2023 to $348.4 billion in 2032, driven partly by architectural trends and design evolution. Manufacturers who can bring new designs to market quickly are better positioned to capitalize on these trends.

The financial implications are substantial. Every week a new product isn't available to customers is a week of lost revenue opportunity. If a new door style could generate $50,000 in monthly sales but the launch is delayed by 8 weeks due to sample production, that's $100,000 in missed revenue before the product even reaches market.

3D visualization also enables rapid product testing and iteration. Before committing to full-scale production, manufacturers can release digital versions of potential new products to gauge customer interest. Analytics show which configurations customers are exploring, which options they're selecting, and where they're abandoning the configuration process. This data informs product development decisions before significant manufacturing investment.

The ability to test and iterate quickly is particularly valuable in an industry with long product lifecycles and significant production setup costs. Traditional approaches required educated guesses about which finishes and options would resonate with customers, backed by sample production that locked in those decisions. Digital visualization enables data-driven decision-making with minimal upfront investment.

For manufacturers working with dealer networks, instant product availability strengthens relationships. Dealers appreciate being able to offer customers new products immediately rather than explaining that samples are "coming soon." This responsiveness improves the dealer's customer experience and makes the manufacturer a more valuable partner.

Threekit designed its platform with this agility in mind. The system integrates with ERP, PIM, and eCommerce platforms, ensuring product data stays synchronized across systems. When a manufacturer adds a new finish to their ERP, it automatically becomes available in the 3D configurator without manual updates. This integration eliminates the technical barriers that might otherwise slow product launches.

Enabling Dealer Networks and Direct-to-Consumer Channels

Door and window manufacturers typically sell through channel structures involving dealers, distributors, contractors, and sometimes direct-to-consumer. Physical samples create challenges across all these channels. Dealers need samples, contractors need references, and direct customers need visualization tools. Supporting all channels with physical samples is expensive and logistically complex.

3D visualization provides a unified solution that works across all channels. Create the digital product once, then deploy it everywhere:

Dealer Showrooms: Interactive displays let customers configure products in real time. Dealers access the full product catalog without physical inventory constraints.

Contractor Tools: Contractors specifying products for projects can show clients photorealistic renderings of recommended products. This tool speeds specification processes and builds client confidence.

Direct-to-Consumer Websites: Manufacturers selling directly can offer the same configuration and visualization capabilities without managing sample inventory or showrooms.

Sales Representative Tools: Field reps can demonstrate unlimited configurations on tablets during customer meetings, replacing physical sample cases that constrain options.

This omnichannel capability ensures consistent product presentation everywhere customers encounter your brand. Whether someone interacts with a dealer, visits your website, or meets with a rep, they see the same photorealistic visualizations and access the same configuration options.

The consistency matters for brand integrity. With physical samples, different channels might show products differently. Samples might be outdated in one location, missing entirely in another, or displayed inconsistently. Digital visualization ensures every customer sees products wholly and accurately, regardless of how they encounter your brand.

For manufacturers, supporting all these channels digitally is far more economical than producing and distributing physical samples everywhere. You make a single investment in 3D model creation, then replicate it across channels at near-zero marginal cost.

Threekit's platform is built specifically for manufacturers selling through detailed channel structures. The technology supports embedded configurators for dealer websites, white-labeled tools for contractor use, and integrated solutions for direct-to-consumer eCommerce. Manufacturers maintain control over product presentation and configuration rules while enabling partners to offer best-in-class digital experiences.

Leading building materials brands trust Threekit for exactly this capability. The platform powers consistent, interactive product experiences across all channels, ensuring customers always receive the same high-quality visualization regardless of where they engage with products. For building materials specifically, Threekit provides industry-optimized solutions that handle the unique requirements of windows, doors, and related categories.

Reducing Catalog Production and Update Costs

Physical product catalogs represent another significant expense for door and window manufacturers. Producing printed catalogs with photography of all product options costs tens or hundreds of thousands of dollars annually, and they become outdated the moment you launch a new finish or discontinue an option.

3D visualization transforms catalog economics. Instead of coordinating photography shoots and print production, manufacturers generate unlimited catalog images from digital models. Need 500 product images for a new catalog? Generate them in days using virtual photography. Want to produce variations for different market segments? Create multiple versions with different product selections with minimal additional effort.

The cost savings are dramatic. Traditional catalog photography, as noted earlier, costs $100-$400 per image. A catalog with 500 product images costs $50,000-$200,000 for photography alone, plus graphic design, printing, and distribution. Virtual photography for the same catalog costs roughly $5,000 for image generation, with similar downstream costs for design and production, but with the flexibility to update continuously.

Digital catalogs eliminate printing and distribution costs entirely. Provide PDFs for download, interactive online catalogs, or app-based product browsers. Customers always access the current product lineup without waiting for printed catalog delivery. When you launch new products or discontinue old ones, update the digital catalog immediately.

This agility is particularly valuable in an industry where product offerings evolve continuously. The 2024 Window + Door Industry Pulse survey highlighted product innovation as a key focus for manufacturers. Communicating innovations to customers immediately through updated digital catalogs accelerates market adoption.

For manufacturers with international markets, digital catalogs eliminate translation and adaptation challenges. Create master digital assets, then localize content for different regions without reproducing photography. Update all regional catalogs simultaneously when products change.

The environmental impact shouldn't be overlooked either. Printed catalogs represent significant paper consumption and carbon emissions from printing and shipping. As sustainability becomes more important to customers and regulations, reducing printed material helps manufacturers meet environmental goals. Digital catalogs are inherently more sustainable while being more effective and less expensive.

Real-World Results: Manufacturers Transforming Sample Economics

The theoretical benefits are compelling, but what about actual results? Manufacturers across the building materials industry are proving that 3D visualization delivers measurable financial and operational improvements.

As noted earlier, companies using 3D virtual photography have seen costs decrease by 6x compared to traditional photography globally, with some Threekit clients reducing costs by 1,000x per image. One manufacturer generated 50,000 product images in one week using Threekit's platform, work that would take months with traditional photography.

Beyond cost savings, manufacturers report improved sales metrics. Threekit data shows that manufacturers using immersive digital experiences see up to 56% more leads compared to standard website visitors. This lead increase comes from improved customer engagement. When people can interact with products digitally, configure options, and visualize results, they're more likely to request quotes and make purchases.

The door and window industry specifically benefits from reduced returns and increased customer satisfaction. When customers can visualize their exact custom configuration before ordering, they're confident their expectations will be met. This confidence translates to lower return rates and fewer customer service issues, both of which improve profitability.

Manufacturers also report improved dealer relationships. By providing dealers with 3D visualization tools, manufacturers help them reduce showroom costs while offering better customer experiences. This value-add strengthens partnerships and makes manufacturers preferred vendors. In an industry where dealer loyalty matters significantly, these relationship improvements create lasting competitive advantages.

The operational benefits extend to internal processes as well. Sales teams report that digital visualization tools help close deals faster because customers can see exactly what they're buying. Quote-to-order times decrease because there's less back-and-forth clarifying specifications. Production planning improves because configured orders contain complete, accurate specifications from the beginning.

A-dec, a leader in dental operatory equipment (and a Threekit customer), recently launched their "Dream in 3D" AI Configurator. Rob Ayers, A-dec's Manager of Digital Customer Experience, noted: "We had a robust configurator in place, but we needed a customer-facing tool to deliver faster, more dynamic, and visually engaging product experiences." The AI Visual Configurator helped A-dec reduce customization clicks and time spent by up to 60% while boosting buyer confidence.

For door and window manufacturers, the opportunity is similar. Products are complex, highly configurable, and difficult to visualize from static images or physical samples. 3D visualization with AI-powered guidance helps customers navigate options efficiently while building confidence in their selections.

Implementation: Getting Started with 3D Visualization

For manufacturers ready to reduce sample costs through 3D visualization, several practical steps enable success. The technology has matured significantly, and implementation no longer requires massive custom development or months of preparation.

First, assess your current sample program costs. Calculate total expenses, including production, shipping, storage, showroom space, catalog photography, and obsolescence. Many manufacturers discover their sample costs are 2-3x higher than initially estimated once all categories are included. This baseline establishes the ROI case for investing in 3D visualization.

Second, identify high-impact product categories for initial implementation. You don't need to visualize your entire catalog immediately. Start with products that offer the most configuration options, have the highest sample costs, or have the strongest customer demand for visualization. This focused approach delivers quick wins that build momentum for broader rollout.

Third, gather product design files. Most manufacturers already have CAD drawings, technical specifications, and product photography that can serve as inputs for 3D model creation. Platforms like Threekit work with various file formats and can build accurate 3D models from existing documentation.

Fourth, choose the right technology partner. Not all 3D visualization platforms are equal, especially for building materials. Look for solutions purpose-built for manufacturers with complex, configurable products. Integration with existing systems (ERP, PIM, eCommerce) is critical for operational efficiency. The platform should handle sophisticated configuration rules, dynamic pricing, and seamless updates when product data changes.

Threekit stands out specifically for building materials manufacturers. The platform is designed for product complexity, with robust configuration logic that handles sophisticated rules around dimensions, materials, and compatibility. The recent launch of Threekit AI for Building Materials demonstrates a specific focus on windows, doors, kitchen, bath, and related categories, where visualization is most valuable.

Fifth, plan for channel deployment. 3D visualization is most valuable when deployed across all customer touchpoints, including dealer showrooms, your direct website, sales rep tools, and contractor resources. Comprehensive deployment maximizes ROI by eliminating sample costs across all channels simultaneously.

Sixth, enable dealer partners with digital tools. Provide dealers with training, marketing materials, and technical support to implement 3D visualization successfully. The more effectively dealers use these tools, the faster you'll see sample cost reductions and improved sales performance.

Seventh, measure results rigorously. Track sample cost savings, lead generation, conversion rates, average order values, and customer satisfaction. Use these metrics to optimize implementation and demonstrate ROI to stakeholders. Most manufacturers see payback within 6-12 months based on sample cost savings alone, with additional revenue benefits accelerating returns.

The technology implementation itself has become straightforward with modern platforms. Threekit's solutions integrate with leading eCommerce platforms, making deployment faster and reducing technical risk. The platform handles the heavy lifting of 3D rendering, configuration logic, and asset management, allowing manufacturers to focus on business outcomes rather than technical details.

The Future of Product Visualization in Building Materials

3D visualization isn't just about eliminating today's sample costs. It's about preparing for tomorrow's buying experiences. Customer expectations continue evolving toward digital-first interactions, and manufacturers who invest in visualization now are positioning themselves for long-term competitive success.

Several trends are accelerating the shift toward digital product visualization:

E-commerce Growth: The building materials industry is moving online, with buyers increasingly expecting to research, configure, and order products digitally. According to Threekit research, comprehensive product content and visualization are essential for the modern B2B buying journey in the building materials industry.

AI Integration: Artificial intelligence is transforming how customers discover and configure products. Natural language interfaces let buyers describe what they need conversationally, with AI recommending appropriate products. Threekit's AI Discovery and Guided Selling capabilities exemplify this evolution.

AR and Spatial Visualization: Augmented reality is becoming mainstream as smartphones and tablets support AR natively. Customers expect to visualize products in their actual spaces before purchasing. The technology that seemed futuristic five years ago is now table stakes.

Sustainability Pressure: Both customers and regulations increasingly favor sustainable practices. Physical samples represent material waste and carbon emissions that digital alternatives eliminate. Manufacturers adopting 3D visualization can position themselves as environmental leaders.

Generational Shifts: Younger buyers and specifiers grew up with digital visualization and expect sophisticated interactive experiences. As this demographic becomes a larger portion of the customer base, demand for digital tools will only increase.

The manufacturers who invest in 3D visualization now are building capabilities that will serve them for decades. As technology continues to improve, rendering quality increases, AI becomes more sophisticated, and AR becomes ubiquitous, early adopters will have established workflows and customer expectations that create lasting advantages.

The financial case is already compelling. The competitive case is becoming urgent. And the customer experience case is undeniable. Physical samples served the industry well for decades, but their limitations are increasingly apparent in an era of infinite product options and digital-first buyers.

Conclusion: The Path to Eliminating Sample Costs

Door and window manufacturers face a clear choice: continue investing in physical sample programs with ever-increasing costs and inherent limitations, or transition to 3D visualization that eliminates sample expenses while providing superior customer experiences.

The economics favor digital visualization overwhelmingly. Reducing sample costs by 90%+ while simultaneously enabling unlimited product configurations, instant new product launches, and omnichannel deployment creates compound benefits that traditional approaches cannot match.

The operational improvements are equally compelling. Faster time-to-market, reduced inventory complexity, streamlined dealer support, and improved customer satisfaction all contribute to stronger business performance beyond direct cost savings.

And the customer experience advantages are undeniable. When buyers can configure products exactly to their specifications, visualize results in real time, and even place virtual products in their actual spaces, confidence increases and sales accelerate. This is the experience modern customers expect, and manufacturers who provide it gain competitive advantages that physical samples cannot deliver.

The technology has matured to the point where implementation risk is minimal and time-to-value is measured in months, not years. Platforms like Threekit provide purpose-built solutions for building materials manufacturers, with proven results across leading brands and specific capabilities for windows, doors, and related categories.

The question isn't whether 3D visualization will replace physical samples. That transition is already underway across the industry. The question is whether your company will lead this transition or follow competitors who recognized the opportunity first. Those who act now will capture the financial benefits of eliminated sample costs while building customer experience advantages that create a lasting market position.

Physical samples served their purpose, but that era is ending. The future belongs to manufacturers who empower customers with unlimited digital visualization and who capture the massive cost savings and operational improvements that technology enables. For door and window manufacturers specifically, this future is already arriving through platforms like Threekit's AI for Building Materials.

The path to eliminating sample costs is clear. The technology is ready. The ROI is compelling. The competitive pressure is real. The only question is when you'll begin the transition.

__________________________________________________

Ready to reduce your sample costs and enable unlimited product visualization? Learn more about Threekit's [visual commerce solutions for building materials](https://www.threekit.com/industry/building-materials) and discover how leading manufacturers are transforming their sample programs and customer experiences.

Sources:

- Grand View Research - Windows And Doors Market Size, Share & Trends Report U.S. Windows And Doors Market (2024-2030) -https://www.grandviewresearch.com/industry-analysis/us-windows-doors-market-report

- Cushman and Wakefield - Industrial Reports - https://www.cushmanwakefield.com/en/united-states/insights/us-marketbeats/us-industrial-marketbeat

- Bureau of Labor Statistics - What price changes contributed the most to increases in the CPI in 2024?- https://www.bls.gov/opub/btn/volume-14/what-price-changes-contributed-the-most-to-increases-in-the-cpi-in-2024.htm#:~:text=Transportation%20prices%20increased%201.6%20percent,U.S.%20Bureau%20of%20Labor%20Statistics.

- WDMA - The 2024 WDMA U.S. Window & Door Industry Market Study- https://www.openuptoperformance.com/2024-window-door-industry-market-study/

- Modelry - 3D virtual photography is 6x cheaper than traditional photography- https://www.modelry.ai/3d-virtual-vs-traditional-photography-cost-comparison

- PR Newswire - Threekit Introduces AI for Building Materials, Helping Buyer, Designers and Pros Identify and Visualize the Right Products in Seconds - https://www.prnewswire.com/news-releases/threekit-introduces-ai-for-building-materials-helping-buyer-designers-and-pros-identify-and-visualize-the-right-products-in-seconds-302599124.html#:~:text=Proven%20Results%2C%20Rapid%20Growth,everyone%20from%20homeowners%20to%20architects.%22

- MRFR - Market Research Future (MRFR) has published on the “Global Windows and Doors Market”. - https://www.marketresearchfuture.com/press-release/windows-doors-market